Products

Fiberglass

Fiberglass is used as a Conductive thermal barrier. Fiberglass insulation is made out of melted sand or recycled glass that is spun into fibers and bonded together. Fiberglass comes in various thicknesses and R-Values. Fiberglass has been the most popular insulation for homes for the last 80+ years. There have been many improvements to the product during that time. The composition of the fibers and how they are bound together and the removal of formaldehyde have improved fiberglass over they years although visually it has remained the same. Fiberglass is most often selected for its low price point, high effectiveness, versitality and wide availability.

Fiberglass comes in three forms: Batts, Rolls and Loosefill.

Batts

Batts come in just about every size and thickness that any job needs as well as the widths and lengths to fit standard framing practices. The most common R-Values available are 11, 13, 15, 19, 21, 23, 25, 30, 30C, 38, 38C, 44, 49 and 60. Batts come in two main forms: Faced and Unfaced.

Faced Batt

Faced batt insulation has paper on one side which acts as a vapor retarder. In our area of California, vapor barriers are not recommended in 95% of installations. Its primary use is for homes at high elevations where the use of a vapor retarder is required by building code. Using a vapor retarder or other vapor barrier in the wrong climate zone can result in mold and mildew in a wall, ceiling or floor structure.

Unfaced batt

Unfaced batt insulation is what is called for by building code in almost all our climate zones here in California. Unfaced batts won’t trap moisture in wall cavities and are best for most homes in our area. Unfaced batt insulation is more readily available in our central California region.

Rolls

Rolls are primarily used for small DIY type projects. A smaller range of R-Values are available in rolls and a much reduced availability of widths. Rolls come with a small coverage area per package are generally not used by professionals. The Pros and Cons of rolled fiberglass are the same as batts.

Loosefill fiberglass

Loosefill fiberglass, often referred to as “blow” is the most versatile fibreglass and is well suited to installing in attics and existing wall cavities where removing the sheetrock or plaster in order to insulate properly. Loosefill fiberglass is installed by being fed into a specialized blow machine. The blow machine grinds up the material to the proper consistency and then blows it though a hose at a specific air pressure. The installer determines the thickness and R-Value of the installed product. Loose fill fiberglass is loved for its consistent R-Value, even around irregular framing, plumbing or electrical. Filling every little crevice in an attic or wall cavity means a big difference in thermal performance.

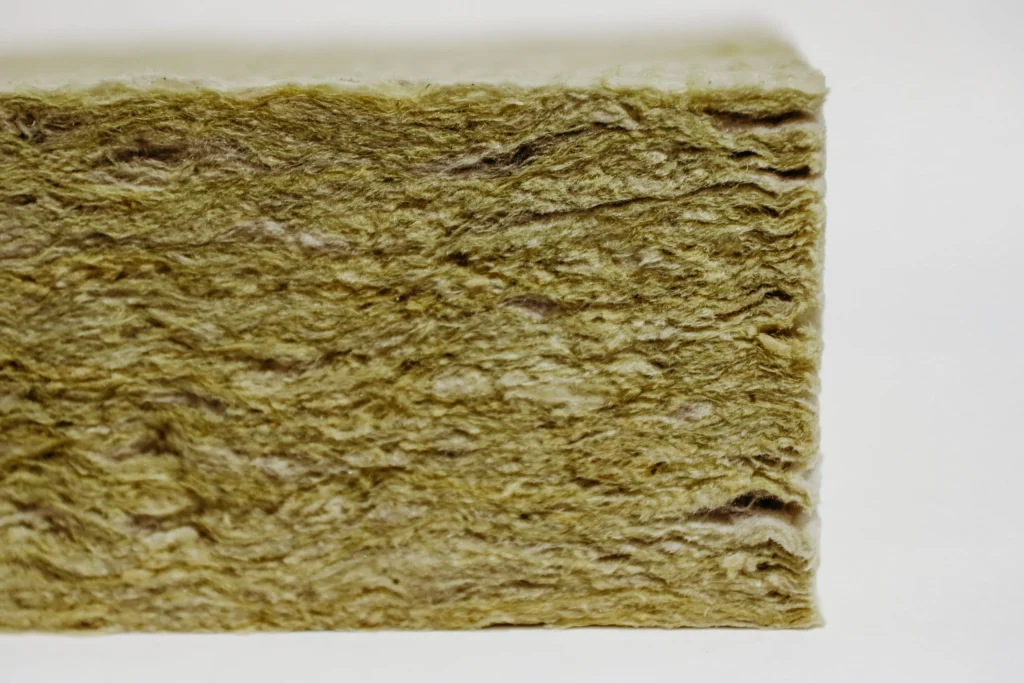

Mineral Wool

Mineral Wool, commonly called Rockwool insulation is used as a Conductive thermal barrier. Mineral Wool is made from melted rocks in a similar way that fiberglass fibers are created. Mineral Wool is prized as a superior alternative to fiberglass for several reasons.

R-Value. Mineral Wool’s density gives it an R-23 in a 2×6 cavity and an R-15 in a 2×4 cavity. These high R-Values consistently outperform fiberglass.

Acoustical

The excellent soundproofing properties of mineral wool surpass fiberglass, cellulose and foam. The density of the material and availability for almost all standard wall and floor cavities make it a natural choice. There is no other product that we would recommend adding to your wall cavities or floors for dampening sound between rooms.

Fireproof

Mineral Wool is completely fire proof to temperatures in excess of 2000 degrees F. For reference, fiberglass insulation melts at about 600 degrees, a typical house fire hits a peak temperature around 1,500 degrees. Mineral Wool is often found in homes after a fire looking the same as when it was installed. (Picture of mineral wool surrounded by ashes here?) Mineral Wool insulation definitely slows fire and can save a life or the home itself by buying precious minutes during a house fire.

Moisture Resistant

Mineral Wool does not absorb moisture which prevents the formation of mold or mildew. Contact with water will also not reduce the R-Value or change the structure of it, whereas fiberglass or cellulose insulation is very negatively effected by water.

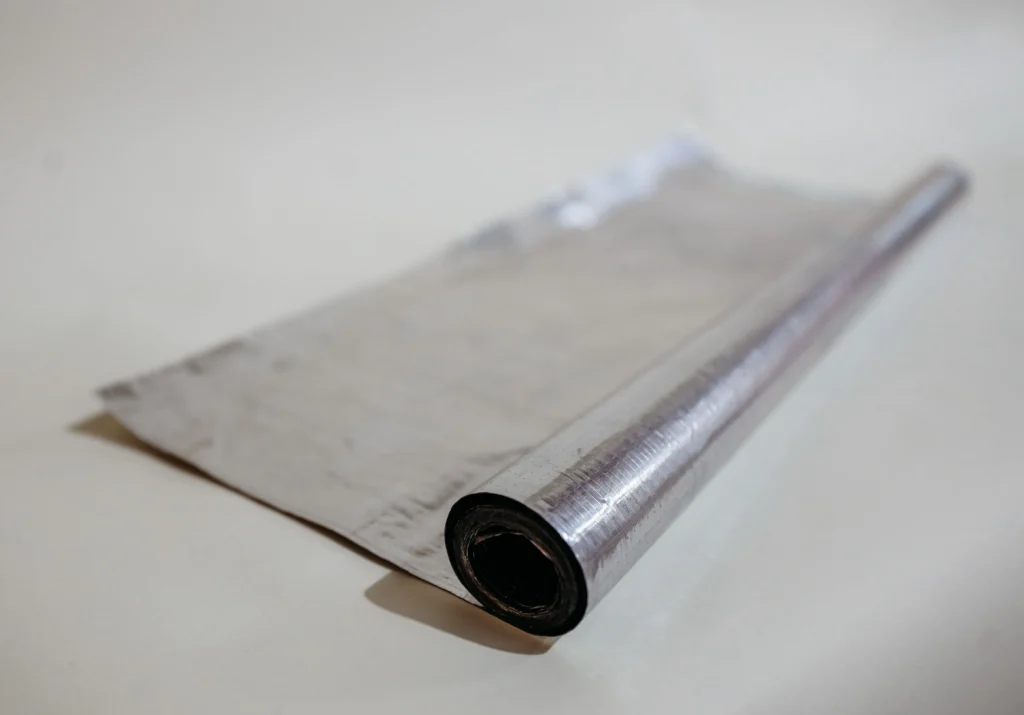

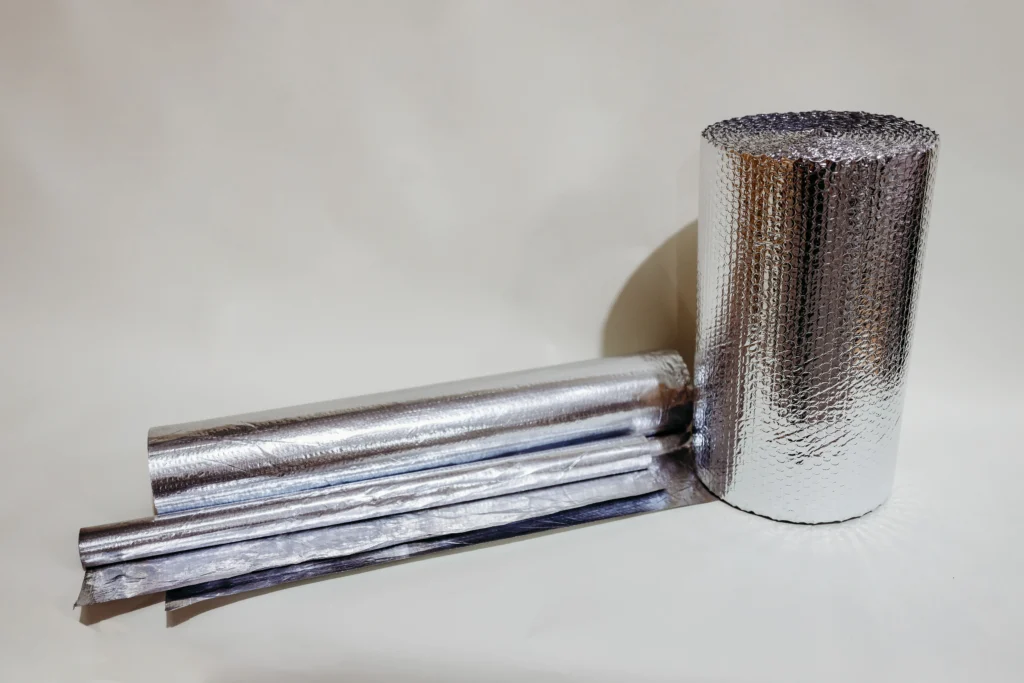

Radient Barrier

Radiant Barrier insulation is used as a Radiant thermal barrier. Radiant barrier insulations are reflective foil faced material, typically the thickness of paper weaved into a strong fabric like material. Radiant barrier insulation is most effective when installed at the underside of your roof and requires an air space on one or both sides. Its benefits are not measured well in “R-Values” but is its own type of insulation with its own specialized benefits. This product reflects the radiant heat put off by your roof back toward itself, preventing a summer attic from quickly raising in temperature which cut cooling costs dramatically. Its benefits are best when installed in a well ventilated attic space.

Radiant heat is the type of heat given off by the sun, it is also the type of heat you can feel coming off a surface without touching it. Any object that heats up will give off radiant heat until its temperature has equalized with the objects around it. That heat can be reflected with a Radiant Barrier.

The general process of Radiant Heat: Radiant heat given off by the sun heats up your roof. That heat conducts through your roof structure. Then the underside of your roof lets off radiant heat waves that heat up anything in a direct line from it. There, the process continues through your ceiling insulation and eventually into your home. A radiant barrier at the roofline blocks that heat and makes it build up between the roof and itself, where most of the heat rises up and ventilates out of your attic.

Foam

Foam is used as both a conductive and convective thermal barrier and Rigid Foam Boards come with a foil Radiant thermal barrier as well. Foam consists of several categories: Rigid Board Foams, Open and Closed Cell Spray Foams and Low Expansion Foam. Hybrid Foam in combination with fiberglass or mineral wool is also a popular option. Foam is made by combining A and B chemical components to product a chemical reaction which expands, solidifies and traps air. Foam has the benefits of a high R-Value per inch thickness and the ability to block air movement.

Rigid Foam Boards

Rigid foam boards come in 4 foot by 8 foot sheets in thicknesses of ½” through 4” thick in increments of ½”. Sheets come with Foil faced, White Vinyl for leaving exposed and Foamular board rated for use under concrete floors. The R-Value per inch thickness is the best available on the market. Its pre formed thicknesses allow for installation in cathedral ceilings when both a ventilation channel and high R-Value are required. Rigid Foam is not air permeable which means it is as excellent at blocking Convective temperature change as it is at blocking Conductive temperature change.

Closed Cell Spray Foam

Spray foam is wildly popular and offers the highest available R-Value per inch thickness, matching rigid foam boards. This method of foam insulation is manufactured on the job site by combining an A and B chemicals pressurized through a gun and sprayed directly on a surface. Spray foam offers solutions to some common problems such as condensation issues in unvented ceiling spaces, achieving high R-Values in limited thickness ceiling, floor or walls and can often be installed with ease, saving on labor costs.

The most common uses for spray foam are for meeting building code requirements for insulation R-Value in a ceiling, wall or floor cavity that has a limited space or to address areas that are prone to moisture and the rot/ mold that For example: If your new home is built with a cathedral ceiling made up of 2x8s and your insulation requirements for that ceiling are to meet R-38, this would be an instance where spray foam would be your only choice. A 2×8 cavity can not achieve an R-38 with fiberglass, Mineral Wool or Cellulose. Spray foam bonds directly to the underside of the roof sheathing and at only a couple inches thick it eliminates the danger of moisture problems and the mold and rot that come with it.

Closed Cell Spray foam is a great long term investment due to its unparalleled performance and energy efficiency. An air tight barrier with high R-Value are what makes closed cell spray foam an all around great performer in any home or building. If your budget allows, spray foam can make an extremely efficient and comfortable home.

Low Expansion Foam

Low expansion foam is a special product that is designed to stop air infiltration in specific areas. This type typically comes in 15oz cans and is installed with a special foam dispensing gun. This is the best way to insulate around doors and windows. The foam fills that edges and creates an air tight seal as well as adding insulation value and is specially designed to expand just enough to seal and insulate but is guaranteed not to warp or bow door or window frames. This type of foam is also used to seal off the areas known to cause air leakage in the ceilings, walls and floors of both new and existing homes.

Hybrid Foam

A combination of closed cell spray foam and fiberglass or mineral wool open up a whole world of possibilities. Example: In a 2×6 cavity (true depth of 5.5”) Adding 2” of closed cell foam will have an R-Value of about 15. This 3.5” remining cavity can be filled with an R-15 fiberglass or mineral wool batt for a total cavity R-Value of 30.

Foam adds a significant R-Value boost, also the benefits of zero air leakage in as little as a layer 1” to 1.5” thick. Now combine that with the low cost of batt insulations and you end up with a very high R-Value with no convective air leakage.

The price of hybrid wall, ceiling or floor cavity insulation is about half the cost of full cavity foam. There is also zero wasted material because the foam does not need to be over sprayed and then cut flush, which is very labor intensive. Oftentimes this is the best choice for home owners who want high efficiency, low air leakage but don’t want to break the bank getting there.

Not sure what insulation is best for you home?

Schedule a free professional evaluation and quote.